参考价格

10-20万元型号

SM 300品牌

德国Retsch(莱驰)产地

德国样本

暂无看了切割式研磨仪 SM 300的用户又看了

留言询价

留言询价 电话询价

电话询价

虚拟号将在 180 秒后失效

使用微信扫码拨号

仪器介绍:

The new Cutting Mill SM 300 excels especially in the tough jobs where other cutting mills fail. The high torque of the new 3 kW drive with additional flywheel mass allows for an exceptionally effective preliminary size reduction of heterogeneous mixtures, such as waste or electronic components. Analytical fineness is often achieved in one working run. The cutting mill is used successfully for a great variety of materials. The sample material is only moderately warmed up during the grinding process so that the mill is also suitable for grinding temperature-sensitive materials.

Another innovation is the wide, freely selectable speed range from 700 to 3,000 min-1. In combination with the wide selection of bottom sieves, hoppers and collecting vessels, the mill can be easily adapted to application requirements.

应用实例:

橡胶, 植物原料, 树脂, 木头, 塑料, 动物饲料, 纸板, 纸张, 纺织品, 稻草, 电子产品废料, 皮革, 香料 , 骨头, 食物, 褐煤, 药品, ...

优点:

* powerful size reduction thanks to 3 kW drive with high torque

* perfect adaptation to application requirements by variable speed from 700 to 3,000 min-1

* optimum cutting effects thanks to double acting cutting bars

* quick and easy cleaning without toolsdue to fold-back housing with smooth surfacesand push-fit rotor

* defined final fineness due to bottom sieves with aperture sizes from 0.25 - 20 mm

* ergonomic design

* wide range of accessories

性能指标:

应用 切割粉碎

应用领域 geology / metallurgy, 工程/电子, 建筑原料, 医药品, 化学 / 合成材料, 环境, 玻璃/ 陶瓷, 生物, 食物

样品特征 软性的, 中硬性, 硬的, 弹性的, 含纤维的

粉碎原理: 剪切力

**进样尺寸 < 60 x 80 mm

*终出料粒度 * 0.25 - 20 mm

网频50赫兹(60赫兹)下的转速 700 - 3000 min-1

旋翼圆周线速度 4.7 - 20.3 m/s

Rotor diameter 129.5 mm

转刀类型 平行切割-旋翼 / 6叶组合式-旋翼

Types of hoppers universal, long stock

转速比设定 1:1

研磨套件材料 硬质刚, 不锈钢, 防重金属研磨钢, 碳化钨

筛网尺寸: trapezoid holes 0.25 / 0.50 / 0.75 / 1.00 / 1.50 mm

square holes 2.00 / 4.00 / 6.00 / 8.00 / 10.00 / 20.00 mm

Collector systems / capacities collecting receptacle 5 l / optional: 30 l

collecting unit 0.25 / 0.5 l

cyclone-suction combination (0.25 l - 5 l)

Cyclone suction unit xl

驱动 三相电机

驱动功率 3 kW with flywheel mass ~ 28.5 kg

Engine brake 是

防护类型 IP 20

机体尺寸(宽x高x纵深) 795 (1090 opened) x 1691 x 765 mm (with base frame and universal hopper)

净重 ~ 160 kg

Documentation Operation & Application Video

Standards CE

Measuring conditions idler neutral gear

受样品材料性质和仪器配置/设定的影响

作用原理:

Size reduction in the Cutting Mill SM 300 takes place by cutting and shearing forces. The sample comes into contact with the rotor, and is comminuted between the blades and the stationary double acting cutting bars inserted in the housing. In the 6-disc rotor, spirally arranged reversible hard metal plates operate by cutting in sequence. The knives of the parallel section rotor carry out comminution with a powerful cutting action. An additional flywheel mass on the drive shaft produces the exceptional performance of the SM 300. Thanks to the variable speed from 700 to 3,000 min-1, the SM 300 can be easily adapted to different application requirements.

暂无数据!

2019年3月15日,中央广播电视总台3·15晚会曝光了危险的辣条,部分生产厂家生产条件极不卫生,无任何卫生防护措施,生产车间触目惊心。当晚11点59分, 国家市场监管总局官网发文称:

2019-04-10

红外吸收法测量钢铁中碳硫元素含量 碳元素、硫元素是确定钢铁产品规格和质量的重要因素,钢铁中碳硫含量的检测—碳硫分析仪,是企业理化分析室中一种常用计量分析仪器,用于对金属和非金属材料中碳和硫元素含量的定

2019-08-06

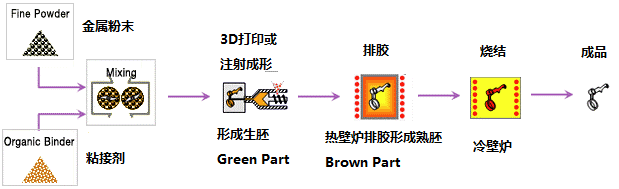

金属增材制造(AM)可分为直接成型和间接成型两种。间接增材制造工艺和粉末注塑成型工艺中(陶瓷注塑成型简称CIM,金属注塑成型简称MIM),初始粉末需要和粘接剂充分混合,生坯成型后,粘合剂则需要

2019-12-03

氮化铝(AlN)陶瓷基片是一种新型的基片材料,具有优异的电性能、力学性能以及热性能,其热导率高(理论热导率280W/m/K)、介电常数低(约为8.8)、拥有与硅Si相匹配的热膨胀系数(293K

2019-12-03

公司更名申明

公司更名申明  Carbolite(卡博莱特)产品综合目录

Carbolite(卡博莱特)产品综合目录  Carbolite(卡博莱特)产品目录四折页

Carbolite(卡博莱特)产品目录四折页  弗尔德科学仪器部杭州技术交流会邀请函

弗尔德科学仪器部杭州技术交流会邀请函  应用报告:机械研磨的方法合成纳米晶体Al-Si-Fe-X合金粉末

应用报告:机械研磨的方法合成纳米晶体Al-Si-Fe-X合金粉末  《The Sample》杂志-仪器分析前的样品制备

《The Sample》杂志-仪器分析前的样品制备  筛分设备系列产品介绍

筛分设备系列产品介绍  行星式球磨仪系列产品介绍

行星式球磨仪系列产品介绍  CryoMill介绍

CryoMill介绍

卡博莱特盖罗重磅发布AriesPlus控制器卡博莱特盖罗 (Carbolite Gero) 正式推出其全新力作——AriesPlus智能控制器!这款控制器以先进算法重新定义操作便捷性与功能强大性,为您

回收和废物管理回收倡议针对的是各种废料,包括电池、建筑垃圾和生物垃圾等日常用品。要重新利用这些不同的材料,通常需要将其粉碎和均质化,使其形成新的形状和新的物品。例如,用废旧瓶子中的碎玻璃颗粒可以制作新

初夏时节,草树花木和阳光都日渐热烈起来,金相行业领导品牌QATM备受瞩目的Qpress 40热镶嵌机也同期火热上市。作为集成了可靠热压镶嵌创新技术的新一代标杆产品,Qpress40将以前所未有的镶嵌速

告别手动繁琐 电子样品的全自动目标切片制备不再遥不可及 在电子领域,金相分析更为常见的名称为“切片”(Cross-sectioning),是揭示选定截面微观结构的一种分析手段,广泛

卡博莱特盖罗其中一款明星产品,可控惰性气氛烘箱HTMA系列已经在光学行业,半导体芯片制造行业,金属热处理行业得到广泛应用。在工艺开始前,用惰性气体置换炉膛内的空气,并在炉膛内保持微正压,避免样品在热处

现代金相制样过程中,如何在满足制备质量要求的前提下简化制样步骤一直从业人员的不懈追求。如今,金相耗材技术的飞速发展使制备步骤简化的梦想轻松可及——在粗磨磨平样品后,原来必需的多道P320-P120砂纸

切割式研磨仪 SM 300的工作原理介绍?

切割式研磨仪 SM 300的工作原理介绍? 切割式研磨仪 SM 300的使用方法?

切割式研磨仪 SM 300的使用方法? 切割式研磨仪 SM 300多少钱一台?

切割式研磨仪 SM 300多少钱一台? 切割式研磨仪 SM 300使用的注意事项

切割式研磨仪 SM 300使用的注意事项 切割式研磨仪 SM 300的说明书有吗?

切割式研磨仪 SM 300的说明书有吗? 切割式研磨仪 SM 300的操作规程有吗?

切割式研磨仪 SM 300的操作规程有吗? 切割式研磨仪 SM 300的报价含票含运费吗?

切割式研磨仪 SM 300的报价含票含运费吗? 切割式研磨仪 SM 300有现货吗?

切割式研磨仪 SM 300有现货吗? 切割式研磨仪 SM 300包安装吗?

切割式研磨仪 SM 300包安装吗? 手机版:

手机版: