常州力马干燥科技有限公司

高级会员

高级会员 已认证

已认证

常州力马干燥科技有限公司

高级会员

高级会员 已认证

已认证

干法制粒机LG-400

Advantage of Lemar Drying Granulation Machine

1. 生产效率 Work efficient

1.1. 螺杆输料系统中抽真空装置使压片更密实,成粒率高

The vacuum device of screw feeding system improves the compactedness, so production efficiency is very high

1.2. 经实验及生产实践,物料成粒率可达80%~90%

According to experiment productive practice, the granulation rate can be 80%~90%

2. 人员健康 Health of operator

2.1. 设备密封性好,生产过程中无粉尘泄漏,保护操作人员身心健康

The sealing condition of the equipment is good, there is no dust flying and powder leakage.

2.2 全封闭结构,无外露传动机构

Full closed structure, there is no exposed transmission device

2.3. PLC智能控制,防止误操作

PLC intelligent control can avoid the misoperation.

3. 设备性能 Performance of equipment

3.1. 液压站、电机及电器元件均采用国内外知名品牌,质量可靠

Hydraulic pressure station, motor and electrical parts are famous brand in China and foreign country. The quality is good and reliable.

3.2. 设备总功率小,节能

The total power is low, and energy saving

3.3 输料螺杆旋转零件上的密封装置选用优质材料,使用寿命长,无需频繁更换

The material sealing device of screw conveyor is good, its using life is long, so frequent replacement is not needed.

3.4. 进料斗有旋转及震动装置,可防止物料搭桥,保证生产过程顺畅

There is rotation and vibration device for feed hopper, it can avoid the bridging phenomenon of material. So the production process is very smooth.

3.5. 零部件精密度高,运行平稳无噪音

The precision of machine parts is high. The machine running is stable and there is no noisy.

3.6. 整理网采用不锈钢编织网焊接,使用寿命长,成粒率高

The milling screen is made and welded of stainless steel wire woven, its using life is long and granulation rate is high.

3.7. 压轮采用特种不锈钢制作而成,硬度大,使用寿命长

The rollers are made of special stainless steel, hardness is high and using life is long

3.8. 采用真空上料及真空出料,大大降低了人工劳动强度

It adopts vacuum feeding and vacuum discharging, labor intensity of operator is reduced greatly.

4. 设备使用 The using of equipment

4.1. 拆卸简单方便:拆卸仅需3分钟,安装仅需5分钟。而其他厂家同类产品拆装需30分钟左右

It is very easy to dismantle: just need 3min to dismantle it and just need 5min to install it. But for the same machine of other factories, it will need about 30min to dismantle or install it.

4.2. 设备整机螺母规格少,所需安装及拆卸工具少,使用方便

The specification of screw nuts and bolts of the machine is less, so the needed install and dismantle tool is less.

4.3. 方便检修及清洗

Very convenient to maintenance and clean.

5. 外形结构 Appearance and structure

5.1. 外形美观,结构合理

Appearance is beautiful and structure is reasonable

5.2. 控制柜与主机一体式安装,占地面积小.

Control cabinet and main machine is all-in-one type installation. Its occupied area is small.

5.3.一体式客户接线,客户电工仅需要将总电源与电柜用电缆连接即可。而其他厂家同类产品电柜与主机为分开式结构,占地面积大,客户电工既需要将总电源与电柜线缆连接,有需要将电柜与各电机分别连接,工作量大。

The all in one type installation is very convenient for client’s electrician to connect wires. Client’s electrician just needs to use cable to connect our control cabinet and power source. But for the same machine of other factories, the control cabinet and main machine is separated type, its occupied area is big. And client’s electrician not only needs to connect the cable between control cabinet and power source, but also needs to connect the cables between control cabinet and all motors, so workload is high.

6. 产品业绩 Achievement of equipment

6.1. 我公司产品已应用于国内数十家制药及化工企业,知名度高,如天津天士力、北京康仁堂、安徽源和堂等

Our drying granulation machine is widely used by dozens of China pharmaceutical factories, and popularity is high. For example: Tianjin Tasly Holding Group Co.,Ltd, Beijing Tamages Pharmaceutical Co.,Ltd, Anhui Yuanhetang Pharmaceutical Co.,Ltd.

6.2. 我公司干法制粒机工程师从事干法制粒机研究、设计与生产工作十余年,经验丰富,技术**

Our company’s engineer of drying granulation machine is engaged in research and design drying granulation machine more than ten years. His work experience is very rich and technology is very advanced.

干法制粒机LG-400的工作原理介绍?

干法制粒机LG-400的工作原理介绍? 干法制粒机LG-400的使用方法?

干法制粒机LG-400的使用方法? 干法制粒机LG-400多少钱一台?

干法制粒机LG-400多少钱一台? 干法制粒机LG-400使用的注意事项

干法制粒机LG-400使用的注意事项 干法制粒机LG-400的说明书有吗?

干法制粒机LG-400的说明书有吗? 干法制粒机LG-400的操作规程有吗?

干法制粒机LG-400的操作规程有吗? 干法制粒机LG-400的报价含票含运费吗?

干法制粒机LG-400的报价含票含运费吗? 干法制粒机LG-400有现货吗?

干法制粒机LG-400有现货吗? 干法制粒机LG-400包安装吗?

干法制粒机LG-400包安装吗?相关产品

更多

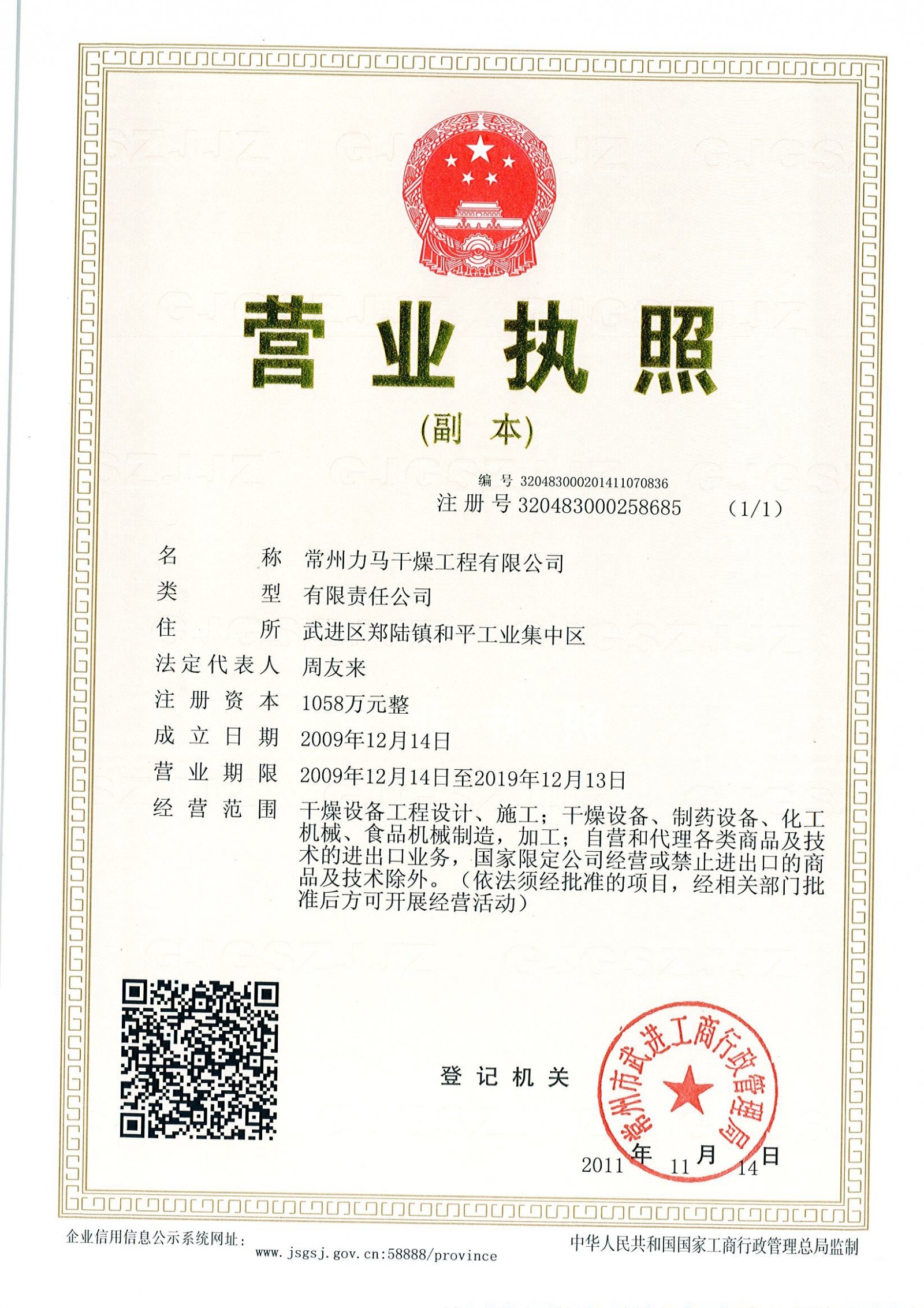

企业名称

常州力马干燥科技有限公司企业类型

信用代码

91320402398292532N法人代表

注册地址

成立日期

注册资本

有效期限

经营范围

虚拟号将在 秒后失效

使用微信扫码拨号